SD

Mainsheet setup and Purchase System

Moderator: GreenLake

Re: Mainsheet setup and Purchase System

Contrary to photographic evidence. I do not fish out of my DS. That pic was taken when it was in storage and my brother in law put those rods in my boat to give to me because he didn't want them any more and was cleaning up the building. LOL.

SD

SD

- Salty Dog

- Posts: 173

- Joined: Tue Nov 06, 2012 11:38 pm

- Location: Canyon Lake, Texas

Re: Mainsheet setup and Purchase System

The instructions from my sailmaker called for a fixed position, with adjustments via Barber haulers.

~ green ~ lake ~ ~

- GreenLake

- Posts: 7434

- Joined: Mon Jun 18, 2007 3:54 am

Re: Mainsheet setup and Purchase System

ok... I see how a barber hauler would tighten the leech as it pulls inboard and down. I guess you could put a block in side the coaming where the track used to be . to get it off the top of the coaming as to not interfere with the crew hiking out. I am not used to having a crew, but in the race I was in I had one the second day and the swivel cleat was in the way of him hiking out.

- Salty Dog

- Posts: 173

- Joined: Tue Nov 06, 2012 11:38 pm

- Location: Canyon Lake, Texas

Re: Mainsheet setup and Purchase System

The barber haulers I rigged are forward of the cockpit. I don't seem to have a good picture of them.

Essentially, they are two, each a line that ends in a block though which the jib sheet is lead. The other end goes to a cleat. I placed the cleats on the edge of the cuddy, so I an pull down on the free ends. The cleats are positioned so that they are closer to the windward side, meaning the barber haulers cross each other.

They mostly pull in, not down.

On a DSII, where you might have cuddy doors, it's inconvenient to have something hang down, so you may want to place the cleats so that the free ends can just lie flat along the cuddy top. And the crosswise arrangement works better, the further out you tend to sit (or hike).

Essentially, they are two, each a line that ends in a block though which the jib sheet is lead. The other end goes to a cleat. I placed the cleats on the edge of the cuddy, so I an pull down on the free ends. The cleats are positioned so that they are closer to the windward side, meaning the barber haulers cross each other.

They mostly pull in, not down.

On a DSII, where you might have cuddy doors, it's inconvenient to have something hang down, so you may want to place the cleats so that the free ends can just lie flat along the cuddy top. And the crosswise arrangement works better, the further out you tend to sit (or hike).

~ green ~ lake ~ ~

- GreenLake

- Posts: 7434

- Joined: Mon Jun 18, 2007 3:54 am

Re: Mainsheet setup and Purchase System

I'm sorry, I reread my post and I didn't make it plain. I have seen the barber haulers rigged up and I'm going to rig me some up also. What I meant about the jib leech was that if the barber haulers were on the cuddy top they would pull in and down on the sheet. the down part would be like moving a car forward.

The block on the side of the coaming I was talking about was the jib sheet block. Mine is on the top of the coaming where my crew would sit hiking out. and I was thinking about moving it to the side of the coaming in the cockpit where the original track used to be. so it would not interfere with hiking out, and running the sheet from there to the cuddy front where I would put a swivel cleat to adjust the sheet.

What do you think?

The block on the side of the coaming I was talking about was the jib sheet block. Mine is on the top of the coaming where my crew would sit hiking out. and I was thinking about moving it to the side of the coaming in the cockpit where the original track used to be. so it would not interfere with hiking out, and running the sheet from there to the cuddy front where I would put a swivel cleat to adjust the sheet.

What do you think?

- Salty Dog

- Posts: 173

- Joined: Tue Nov 06, 2012 11:38 pm

- Location: Canyon Lake, Texas

Re: Mainsheet setup and Purchase System

Salty Dog wrote:I'm sorry, I reread my post and I didn't make it plain. I have seen the barber haulers rigged up and I'm going to rig me some up also. What I meant about the jib leech was that if the barber haulers were on the cuddy top they would pull in and down on the sheet. the down part would be like moving a car forward.

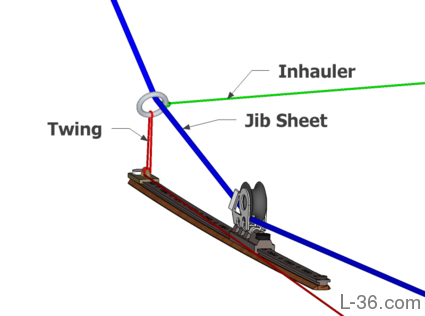

I guessed the former part, but wasn't sure. The function of a barber haulers is usually to pull in. Mine are at a slight angle to the horizontal; less than 15 degrees. So they effectively don't pull down. To get the effect you want, you'd need a twing.

Salty Dog wrote:The block on the side of the coaming I was talking about was the jib sheet block. Mine is on the top of the coaming where my crew would sit hiking out. and I was thinking about moving it to the side of the coaming in the cockpit where the original track used to be. so it would not interfere with hiking out, and running the sheet from there to the cuddy front where I would put a swivel cleat to adjust the sheet.

What do you think?

My sailmaker suggested a fixed position for the jib fairlead corresponding approximately to the forward end of the jib track, and not contemplating any adjustments. I'm not sure whether I agree - but then I often sail in lighter winds. If you follow the advice he gave (and for all I know they could be specific to the way he cut the jib) then you wouldn't want a twing - because that helps if your fairlead is too far back in some conditions.

Note the use of a ring, instead of block. Opinions seem to differ. Some here have reported poor experience with rings. My thought is that it may be a matter of how slippery your jib sheet is. I used to have three-stranded jib sheets (original to the boat, I assume). Those would not slide well through a ring. But now I have a rather smooth sheet, but I have the blocks for the barber haulers anyway.

~ green ~ lake ~ ~

- GreenLake

- Posts: 7434

- Joined: Mon Jun 18, 2007 3:54 am

Re: Mainsheet setup and Purchase System

GL

I bought 2 ronstan low friction rings. I'm going to use them on my barber haulers. I'll see if they work.

I knew the jib clew was kinda high above the cuddy top on DS. That's why I though I would get some down haul on the BH, but you're right prob not.

I am mostly into single hand leisure sailing. But I have found myself in the situation of being in a DS fleet at canyon Lake and they are racing on a regular basis. I like racing, but I keep finding myself in last place. I have fun and lots of comradery. But It has steered up an interest in go fast gadgets. and having a crew. Now that I'm retired I Have Time to tinker.

SD

I bought 2 ronstan low friction rings. I'm going to use them on my barber haulers. I'll see if they work.

I knew the jib clew was kinda high above the cuddy top on DS. That's why I though I would get some down haul on the BH, but you're right prob not.

I am mostly into single hand leisure sailing. But I have found myself in the situation of being in a DS fleet at canyon Lake and they are racing on a regular basis. I like racing, but I keep finding myself in last place. I have fun and lots of comradery. But It has steered up an interest in go fast gadgets. and having a crew. Now that I'm retired I Have Time to tinker.

SD

- Salty Dog

- Posts: 173

- Joined: Tue Nov 06, 2012 11:38 pm

- Location: Canyon Lake, Texas

Re: Mainsheet setup and Purchase System

If you can get fun and camaraderie out of it, then racing is definitely worthwhile, even if you have to fight for last place.

And it will improve your boat handling. Whether it's dealing with traffic, sail trim, observing the wind, balance and steering.

Reward yourself with a new gadget every once in a while, but I'd suggest spacing them out, so you have a chance to get the best out of each, before you add the next one into the mix.

And it will improve your boat handling. Whether it's dealing with traffic, sail trim, observing the wind, balance and steering.

Reward yourself with a new gadget every once in a while, but I'd suggest spacing them out, so you have a chance to get the best out of each, before you add the next one into the mix.

~ green ~ lake ~ ~

- GreenLake

- Posts: 7434

- Joined: Mon Jun 18, 2007 3:54 am

Re: Mainsheet setup and Purchase System

It looks like the topic has shifted a bit towards inhalers, but wanted to give a quick update on the sheeting mods. My brother in law and I went out to test the new gizmos on the boat this past weekend. Unfortunately we had an issue with the trailer that caused us to spend quite a bit of time fixing before we could get out. But once we got that wrapped up we had about an hour of sail time left after we made the ramp and launched. Not that I am the most qualified sailer, but even for me it was a substantial improvement to have the swivel cam on the main sheeting system with the ratchet block. Holding the sheet in hand is now easy, and cleating it off and to do other thing just as simple. No worries about hiking out on the edge of the boat. Pretty consistent pulls for cleating and holding the sheet in hand from all sitting areas. For whatever reason we never put up the jib, so I do not have any feedback on that change yet. But will update when I get another chance to get out. Thanks again to everyone for all their input and advice. The boat is becoming more fun to sail!

- DigitalMechanic

- Posts: 374

- Joined: Sat Nov 07, 2015 7:00 am

- Location: Jacksonville, FL

Re: Mainsheet setup and Purchase System

It looks like the topic has shifted a bit towards inhalers...

Now, that's really going off topic

I had just finished banishing the last vestiges of the search traffic hack for those on-line SPAM! pharma, and now you guys want to talk about inhalers.

~ green ~ lake ~ ~

- GreenLake

- Posts: 7434

- Joined: Mon Jun 18, 2007 3:54 am

Re: Mainsheet setup and Purchase System

Whoops... lol. That was supposed to read "in-haulers". Got one past the spell checker again...

- DigitalMechanic

- Posts: 374

- Joined: Sat Nov 07, 2015 7:00 am

- Location: Jacksonville, FL

- Salty Dog

- Posts: 173

- Joined: Tue Nov 06, 2012 11:38 pm

- Location: Canyon Lake, Texas

Re: Mainsheet setup and Purchase System

This pic. was taken before I had ran the vang thru the top and back to the cockpit. also before I had cut the excess line off the vang. I don't know why I did not get a pic. when finished. I guess I was too tired. 2 things: 1) I tried to put 20:1 vang on, but I had to gather so much line to add tention my blocks were together. I will have to move the boom bale back to give me more room for 20:1. I'm going with 10:1 to see how it works. 2) my thru top vang line rubs on my halyard when boom is over the beam. When I am using the vang for closing the twist on the main which will be most loaded time. boom will be along stim so should be fine. I will put it in the water next time I'm at the lake. Prob after Christmas.

- Salty Dog

- Posts: 173

- Joined: Tue Nov 06, 2012 11:38 pm

- Location: Canyon Lake, Texas

Re: Mainsheet setup and Purchase System

I just made a 10:1 vang this week. Its looks almost identical to yours, except mine still lashes around the front of the mast. I can't see the top part of yours, but we reused that little slide in ball thing on the end of a piece of wire rigging as well (not sure what it is called. but was the original way the vang attached to the boom). 10:1 seems to bend my mast with little effort now compared to the 3:1 vang that was on there. But that may just be my mast. Good news is that if later feel I need 20:1 for whatever reason, that is only a 1 block addition.

Looks like you changed the blocks for your halyards as well. Did you do that help with the jib sheet snagging?

Looks like you changed the blocks for your halyards as well. Did you do that help with the jib sheet snagging?

- DigitalMechanic

- Posts: 374

- Joined: Sat Nov 07, 2015 7:00 am

- Location: Jacksonville, FL

Who is online

Users browsing this forum: No registered users and 42 guests